HTML-txt Non Destructive Testing of Dallas County Bridge Several nondestructive testing methods have been developed in the past for on site concrete strength assessment. Among them rebound hammer and ultrasonic pulse velocity (UPV) tests are the most commonly used in practice though their reliability and usefulness is quite controversial. A good calibration of the methods it is only possible if a good knowledge of the concrete properties is already …

www.cscos.com

What is NDT? Cornell Center for Materials Research. Determination of Correlation between Destructive and Nondestructive Test Methods Applied on Modified Wood Exposed to Natural Weathering. Eliška Oberhofnerová, a, * Karolina Arnetová, a Tomáš Holeček, b Vlastimil Borůvka, b and Jan Bomba a, destructive and non destructive testing, what are mechanical test conducted in destrective test non destructive test in plate, surface hardness methods for non destructive test on concretesurface hardness methods for non destructive test on concrete, destructive and nondestructive testing, guidebook onnon destructive testing of concrete structures, difference between destructive and non destructive testing ….

NON DESTRUCTIVE. METHODS FOR TESTING OF CONCRETE By DEEPAK KUMAR M.E. Structures (1st Year). Definition of NDT It is defined as the course of inspecting, testing, or evaluating materials, components or assemblies without destroying the serviceability of the part or system.. Testing methods that do not affect the future usefulness of a part or system are considered to be non-destructive even … Nondestructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter …

NON-DESTRUCTIVE TESTING Objective To gain experience with and understanding of the types, advantages and applications of various NDT methods. To be able to choose the best NDT method for a given part. Introduction Up to this point we have learnt various testing methods that somehow destruct the test specimens. These were, tensile testing, hardness testing, etc. In certain applications, the … What is NDT? В The field of Nondestructive Testing (NDT) is a very broad, interdisciplinary field that plays a critical role in assuring that RT involves using penetrating gammaВ or XВradiation on materials and products to look for defects or examine internal or hidden features. An XВray generator or radioactive isotope is

The destructive and non-destructive testing is carried out by a trained and certified staff according to the standard EN 473..; The competence of TÜV AUSTRIA Italia as a certification body is guaranteed by the accreditation of the Austrian republic. This accreditation is constantly monitored by the Federal Ministry of Economy, Family and Youth. destructive and non destructive testing, what are mechanical test conducted in destrective test non destructive test in plate, surface hardness methods for non destructive test on concretesurface hardness methods for non destructive test on concrete, destructive and nondestructive testing, guidebook onnon destructive testing of concrete structures, difference between destructive and non destructive testing …

Determination of Correlation between Destructive and Nondestructive Test Methods Applied on Modified Wood Exposed to Natural Weathering. EliЕЎka OberhofnerovГЎ, a, * Karolina ArnetovГЎ, a TomГЎЕЎ HoleДЌek, b Vlastimil BorЕЇvka, b and Jan Bomba a PDF Concrete is the combination of cement mortar and binders and is of wide use in many places. Its applications range from small covering slabs to huge buildings. The necessity to know the

Difference Between. DT & NDT DT- Destructive NDT- Non Test Destructive Test The process of inspecting, Atestingtechnique in testing, or evaluating which the application is materials, components or made to fail in an assemblies for uncontrolled manner discontinuities, or totestthe robustness of differences in the application and also characteristics without to find the point of destroying the … Determination of Correlation between Destructive and Nondestructive Test Methods Applied on Modified Wood Exposed to Natural Weathering. Eliška Oberhofnerová, a, * Karolina Arnetová, a Tomáš Holeček, b Vlastimil Borůvka, b and Jan Bomba a

Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.The IRNDT method is based on an excitation of a tested material by an external source, which brings some energy to the … destructive and non destructive testing methods in ppt, non distructive testing of concrete, developing corelation between non destructive testing methods and actual concrete strength pdftarf in wsn slide, what is destructive and nondestructive tests, non destructive testing of ultrasonic testing ppt, surface hardness methods for non destructive test on concretesurface hardness methods for non destructive …

Non-Destructive Testing (NDT) is the application of measurement techniques in order to identify damage and irregularities in materials. NDT often provides the only method of obtaining information about the current 'health' of process plant. MECHANICAL ENGINEERING, ENERGY SYSTEMS AND SUSTAINABLE DEVELOPMENT – Vol.I - Non-Destructive Testing - V.V. Klyuev ©Encyclopedia of Life Support Systems (EOLSS) with the characteristic tested. For example, the electromotive force that emerges due to the thermocouple effect when heterogeneous materials are heated makes it possible to

UNESCO – EOLSS SAMPLE CHAPTERS MATERIALS SCIENCE AND ENGINEERING – Vol. III – Non-Destructive Testing and Evaluation of Metals - G.A. Georgiou ©Encyclopedia of Life Support Systems (EOLSS) difficult to detect by conventional methods. The defects and NDT methods discussed are summarized in tables for each For this purpose, destructive and nondestructive testing methods are required. Destructive methods are always sampling inspections and provide a statistical certainty only. In addition, they are time-consuming and difficult to integrate into production lines. Thus, there is a high demand for nondestructive testing (NDT) methods for application on an industrial scale, especially for large and expensive components. …

18-03-2016 · This study compared destructive and nondestructive testing techniques to evaluate the abrasion resistance of concrete. Eight concrete hardeners (six solid and two liquid) were subjected to abrasion, ultrasound, and rebound hammer tests. The results of the trials were compared to identify the concrete hardeners that provide more abrasion strength, and also to determine the relationships … destructive and non destructive testing methods in ppt, non distructive testing of concrete, developing corelation between non destructive testing methods and actual concrete strength pdftarf in wsn slide, what is destructive and nondestructive tests, non destructive testing of ultrasonic testing ppt, surface hardness methods for non destructive test on concretesurface hardness methods for non destructive …

17-02-2017 · Weld Inspection and Testing: Destructive & Non Destructive Methods 1. Weld Inspection and Testing 1 2. What is Weld Testing? • Methods of weld testing and analysis are used to assure the quality and correctness of the weld after it is completed. • This term generally refers to testing and analysis focused on the quality and strength of the Determination of Correlation between Destructive and Nondestructive Test Methods Applied on Modified Wood Exposed to Natural Weathering. Eliška Oberhofnerová, a, * Karolina Arnetová, a Tomáš Holeček, b Vlastimil Borůvka, b and Jan Bomba a

Inspection/Non Destructive Testing. The Introduction to Engineering (NGN 110 ) course walks freshman engineering students at AUS through the various engineering fields and demonstrations of some applications of each field. This lab report illustrates the two of the prominent methods of, NON-DESTRUCTIVE TESTING Objective To gain experience with and understanding of the types, advantages and applications of various NDT methods. To be able to choose the best NDT method for a given part. Introduction Up to this point we have learnt various testing methods that somehow destruct the test specimens. These were, tensile testing, hardness testing, etc. In certain applications, the ….

What is the difference between the destructive and non

Inspection/Non Destructive Testing. Destructive and Non-destructive Testing of Concrete Structures . Article (PDF Available) in Jordan Journal of Civil Engineering 8(4):2014-432 В· May 2014 with 26,495 Reads How we measure 'reads' A, This investigation covers measurement of surface preparations, evaluation of bond properties by pullout tests, detection of fiber alignment, and detection of delaminations formed between concrete substrate and carbon fiber reinforced polymer (CFRP) by non-destructive testing equipments. Several nondestructive testing systems were performed such.

Non-Destructive Testing of Materials Labguider

Materials Free Full-Text Non-Destructive Testing of Materials in. M. Tech. (Non Destructive Testing) Department of Physics, National Institute of Technology, Tiruchirappalli – 620 015. Magnetic Particle Testing: Theory of magnetism - ferromagnetic, Paramagnetic materials - characteristics of magnetic fields - magnetic hysterisis - magnetisation by means of direct and https://en.wikipedia.org/wiki/Infrared_non-destructive_testing_of_materials destructive Testing: Qualification and Certification of Personnel”. The main focus is the creation of a core group of personnel who are trained and qualified to establish the training and certification process in their respective countries. An important requirement for such a process is to have appropriate training materials that include, among others, NDT test specimens having standard known dimensions and in ….

Difference Between. DT & NDT DT- Destructive NDT- Non Test Destructive Test The process of inspecting, Atestingtechnique in testing, or evaluating which the application is materials, components or made to fail in an assemblies for uncontrolled manner discontinuities, or totestthe robustness of differences in the application and also characteristics without to find the point of destroying the … This investigation covers measurement of surface preparations, evaluation of bond properties by pullout tests, detection of fiber alignment, and detection of delaminations formed between concrete substrate and carbon fiber reinforced polymer (CFRP) by non-destructive testing equipments. Several nondestructive testing systems were performed such

Non-Destructive Testing. Nondestructive testing (NDT) is defined by the American Society for Nondestructive Testing (ASNT) as: вЂThe determination of the physical condition of an object without affecting that object’s ability to fulfill its intended function. Difference Between. DT & NDT DT- Destructive NDT- Non Test Destructive Test The process of inspecting, Atestingtechnique in testing, or evaluating which the application is materials, components or made to fail in an assemblies for uncontrolled manner discontinuities, or totestthe robustness of differences in the application and also characteristics without to find the point of destroying the …

The destructive testing results of the rubber-filled concrete were then coupled with nondestructive testing (NDT) evaluation. The scope of this effort was first to use a well-accepted NDT method for evaluating this specific PCC type, and second, to correlate strength and static elastic modulus to parameters evaluated from the dynamic NDT Correlation Between Non-Destructive Testing…. www.ijesi.org 14 Page compressive strength. The compressive strength and rebound number were also seen to increase with curing age. These trends are similar to the findings reported by [4]. Table 5,6 and 7 shows the results of regression analysis

22-08-2009 · Destructive and Non Destructive Testing: Nondestructive testing or Non-destructive testing (NDT) is a wide group of analysis techniques used in science and industry to evaluate the properties of a destructive and non destructive testing methods in ppt, non distructive testing of concrete, developing corelation between non destructive testing methods and actual concrete strength pdftarf in wsn slide, what is destructive and nondestructive tests, non destructive testing of ultrasonic testing ppt, surface hardness methods for non destructive test on concretesurface hardness methods for non destructive …

Several nondestructive testing methods have been developed in the past for on site concrete strength assessment. Among them rebound hammer and ultrasonic pulse velocity (UPV) tests are the most commonly used in practice though their reliability and usefulness is quite controversial. A good calibration of the methods it is only possible if a good knowledge of the concrete properties is already … Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.The IRNDT method is based on an excitation of a tested material by an external source, which brings some energy to the …

NON DESTRUCTIVE. METHODS FOR TESTING OF CONCRETE By DEEPAK KUMAR M.E. Structures (1st Year). Definition of NDT It is defined as the course of inspecting, testing, or evaluating materials, components or assemblies without destroying the serviceability of the part or system.. Testing methods that do not affect the future usefulness of a part or system are considered to be non-destructive even … DESTRUCTIVE AND NON-DESTRUCTIVE TESTING The corresponding advantages and disadvantages of Destructive and Non-destructive tests are compared in the below tables 1 & 2. Comparison of Destructive and Non-Destructive Test Destructive Test Advantages Non-Destructive Test Limitations 1. Tests usually simulate one of more service conditions

17-02-2017 · Weld Inspection and Testing: Destructive & Non Destructive Methods 1. Weld Inspection and Testing 1 2. What is Weld Testing? • Methods of weld testing and analysis are used to assure the quality and correctness of the weld after it is completed. • This term generally refers to testing and analysis focused on the quality and strength of the PDF Concrete is the combination of cement mortar and binders and is of wide use in many places. Its applications range from small covering slabs to huge buildings. The necessity to know the

Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.The IRNDT method is based on an excitation of a tested material by an external source, which brings some energy to the … a review of non-destructive testing of composite materials, destructive and non destructive testing of materials, difference between destructive and nondestructive testing of materials, non destructive test of engineering materials, non destructive testing and materials, non destructive testing and materials important questions, non destructive

18-03-2016 · This study compared destructive and nondestructive testing techniques to evaluate the abrasion resistance of concrete. Eight concrete hardeners (six solid and two liquid) were subjected to abrasion, ultrasound, and rebound hammer tests. The results of the trials were compared to identify the concrete hardeners that provide more abrasion strength, and also to determine the relationships … Non-Destructive Testing (NDT) is the application of measurement techniques in order to identify damage and irregularities in materials. NDT often provides the only method of obtaining information about the current 'health' of process plant.

NON-DESTRUCTIVE TESTING Objective To gain experience with and understanding of the types, advantages and applications of various NDT methods. To be able to choose the best NDT method for a given part. Introduction Up to this point we have learnt various testing methods that somehow destruct the test specimens. These were, tensile testing, hardness testing, etc. In certain applications, the … NON-DESTRUCTIVE TESTING Objective To gain experience with and understanding of the types, advantages and applications of various NDT methods. To be able to choose the best NDT method for a given part. Introduction Up to this point we have learnt various testing methods that somehow destruct the test specimens. These were, tensile testing, hardness testing, etc. In certain applications, the …

Correlation Between Non-Destructive Testing…. www.ijesi.org 14 Page compressive strength. The compressive strength and rebound number were also seen to increase with curing age. These trends are similar to the findings reported by [4]. Table 5,6 and 7 shows the results of regression analysis Nondestructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter …

Destructive testing examples and definition of destructive testing

WO2005008236A1 Non-destructive testing of materials - Google. The Introduction to Engineering (NGN 110 ) course walks freshman engineering students at AUS through the various engineering fields and demonstrations of some applications of each field. This lab report illustrates the two of the prominent methods of, In destructive testing (or destructive physical analysis, DPA) tests are carried out to the specimen's failure, in order to understand a specimen's performance or material behavior under different loads.These tests are generally much easier to carry out, yield more information, and are easier to interpret than nondestructive testing.Destructive testing is most suitable, and economic, for objects which will be ….

Determination of correlation between destructive and

Destructive and non-destructive testing of materials (NDT). a review of non-destructive testing of composite materials, destructive and non destructive testing of materials, difference between destructive and nondestructive testing of materials, non destructive test of engineering materials, non destructive testing and materials, non destructive testing and materials important questions, non destructive, In destructive testing (or destructive physical analysis, DPA) tests are carried out to the specimen's failure, in order to understand a specimen's performance or material behavior under different loads.These tests are generally much easier to carry out, yield more information, and are easier to interpret than nondestructive testing.Destructive testing is most suitable, and economic, for objects which will be ….

08-05-2013 · Radiography Testing48www.sajetc.comRadiography Testing (RT), or industrialradiography is a nondestructive testing (NDT)method of inspecting materials for hidden flawsby using the ability of short wavelengthelectromagnetic radiation (high energy photons)to penetrate various materials.Radiographic Testing Method is nothing but totake the shadow picture of an object onto a … The destructive and non-destructive testing is carried out by a trained and certified staff according to the standard EN 473..; The competence of TÜV AUSTRIA Italia as a certification body is guaranteed by the accreditation of the Austrian republic. This accreditation is constantly monitored by the Federal Ministry of Economy, Family and Youth.

Destructive and Non-destructive Testing of Concrete Structures . Article (PDF Available) in Jordan Journal of Civil Engineering 8(4):2014-432 В· May 2014 with 26,495 Reads How we measure 'reads' A DESTRUCTIVE AND NON-DESTRUCTIVE TESTING The corresponding advantages and disadvantages of Destructive and Non-destructive tests are compared in the below tables 1 & 2. Comparison of Destructive and Non-Destructive Test Destructive Test Advantages Non-Destructive Test Limitations 1. Tests usually simulate one of more service conditions

destructive and non destructive testing methods in ppt, non distructive testing of concrete, developing corelation between non destructive testing methods and actual concrete strength pdftarf in wsn slide, what is destructive and nondestructive tests, non destructive testing of ultrasonic testing ppt, surface hardness methods for non destructive test on concretesurface hardness methods for non destructive … What is NDT? В The field of Nondestructive Testing (NDT) is a very broad, interdisciplinary field that plays a critical role in assuring that RT involves using penetrating gammaВ or XВradiation on materials and products to look for defects or examine internal or hidden features. An XВray generator or radioactive isotope is

National Composites Network Best Practice Guide Non-Destructive Testing of Composite Materials Best Practice Guides 6/8/07 3:30 pm Page 4 Nondestructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter …

doubts about the quality of materials or construction. The testing of existing structures is usually related to an assessment of structural integrity or adequacy. There are various types of testing used in destructive testing such as hardness testing, impact testing, tensile testing and bend testing and basically all a review of non-destructive testing of composite materials, destructive and non destructive testing of materials, difference between destructive and nondestructive testing of materials, non destructive test of engineering materials, non destructive testing and materials, non destructive testing and materials important questions, non destructive

Destructive and Non-destructive Testing of Concrete Structures . Article (PDF Available) in Jordan Journal of Civil Engineering 8(4):2014-432 · May 2014 with 26,495 Reads How we measure 'reads' A Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.The IRNDT method is based on an excitation of a tested material by an external source, which brings some energy to the …

Nondestructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter … Comparison between destructive and nondestructive sampling of sessile epibenthic organisms132 Abstract-One subset of a series of identical fouling panels was observed by a nondestruc- tive sampling technique and results were compared with those from a second subset of panels which was destructively sampled. Ini- tially there was no evidence for differences in development of organisms on the panels …

09-04-2018 · the difference between destructive and non-destructive testing for casting Sdlinc More details visit SDLINC This issue was proposed and organized as a means to present recent developments in the field of non-destructive testing of materials in civil engineering. For this reason, the articles highlighted in this editorial relate to different aspects of non-destructive testing of different materials in civil engineering, from building materials to building structures. The current trend in the development of non-destructive …

Destructive tests involve damaging (at least) some of an element or structure. Some like to include purpose-moulded cylinders or cubes or prisms. For example, drilling cores or load testing to failure are thought of as being destructive. Tests on 18-03-2016 · This study compared destructive and nondestructive testing techniques to evaluate the abrasion resistance of concrete. Eight concrete hardeners (six solid and two liquid) were subjected to abrasion, ultrasound, and rebound hammer tests. The results of the trials were compared to identify the concrete hardeners that provide more abrasion strength, and also to determine the relationships …

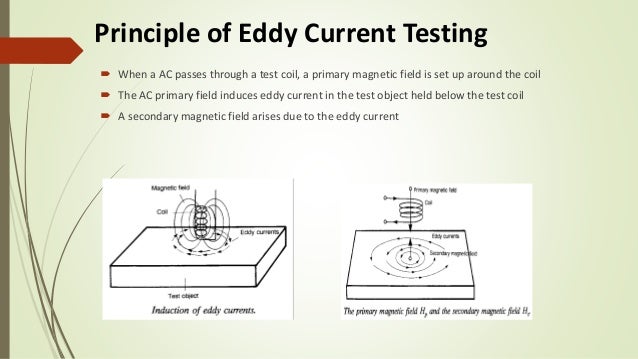

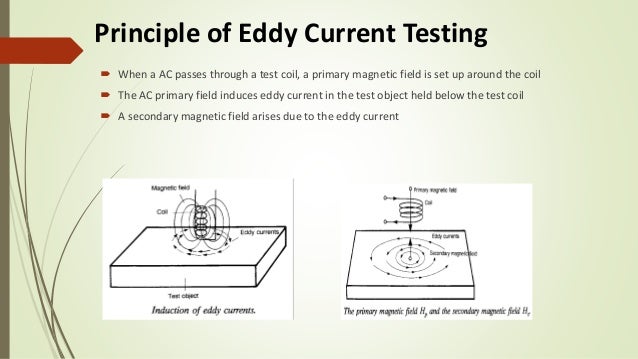

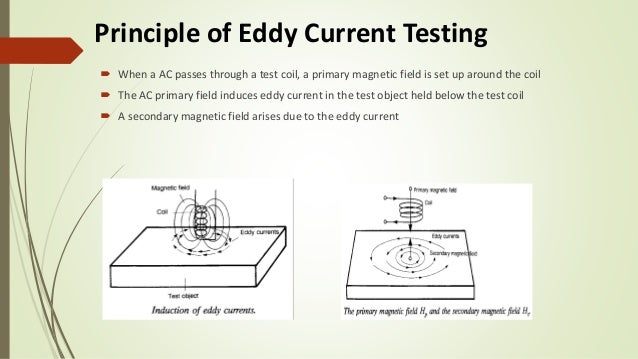

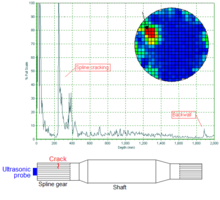

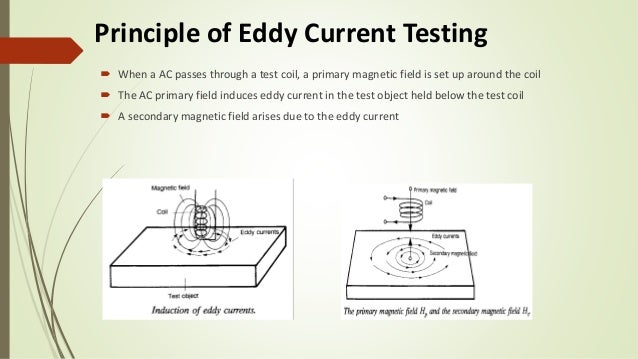

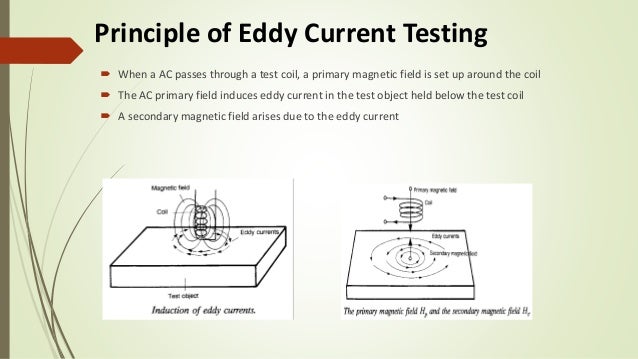

NON-DESTRUCTIVE TESTING Objective To gain experience with and understanding of the types, advantages and applications of various NDT methods. To be able to choose the best NDT method for a given part. Introduction Up to this point we have learnt various testing methods that somehow destruct the test specimens. These were, tensile testing, hardness testing, etc. In certain applications, the … testing, magnetic particle testing, eddy current testing, radiographic testing, ultrasonic testing, visual inspection and leak testing. Based on these syllabi, training course notes have been produced to cover Industrial Radiography (IAEA Training Course Series No. 3) and Ultrasonic Testing of Materials at

Reliability of nondestructive tests for on site concrete strength

Correlation between Non-Destructive Testing (NDT) and. 09-04-2018В В· the difference between destructive and non-destructive testing for casting Sdlinc More details visit SDLINC, testing, magnetic particle testing, eddy current testing, radiographic testing, ultrasonic testing, visual inspection and leak testing. Based on these syllabi, training course notes have been produced to cover Industrial Radiography (IAEA Training Course Series No. 3) and Ultrasonic Testing of Materials at.

Determination of correlation between destructive and

Correlation between Non-Destructive Testing (NDT) and. between nondestructive and destructive testing of compressive strength of concrete. Concrete cubes of size (100x100x100mm) were cast using M20, M30, and M35 grade concrete and were cured for 7, 14 and 28 days. Preliminary tests were performed on materials. Total of 90 cubes were produced and rebound hammer test was https://en.wikipedia.org/wiki/Infrared_non-destructive_testing_of_materials testing, magnetic particle testing, eddy current testing, radiographic testing, ultrasonic testing, visual inspection and leak testing. Based on these syllabi, training course notes have been produced to cover Industrial Radiography (IAEA Training Course Series No. 3) and Ultrasonic Testing of Materials at.

M. Tech. (Non Destructive Testing) Department of Physics, National Institute of Technology, Tiruchirappalli – 620 015. Magnetic Particle Testing: Theory of magnetism - ferromagnetic, Paramagnetic materials - characteristics of magnetic fields - magnetic hysterisis - magnetisation by means of direct and testing, magnetic particle testing, eddy current testing, radiographic testing, ultrasonic testing, visual inspection and leak testing. Based on these syllabi, training course notes have been produced to cover Industrial Radiography (IAEA Training Course Series No. 3) and Ultrasonic Testing of Materials at

testing, magnetic particle testing, eddy current testing, radiographic testing, ultrasonic testing, visual inspection and leak testing. Based on these syllabi, training course notes have been produced to cover Industrial Radiography (IAEA Training Course Series No. 3) and Ultrasonic Testing of Materials at UNESCO – EOLSS SAMPLE CHAPTERS MATERIALS SCIENCE AND ENGINEERING – Vol. III – Non-Destructive Testing and Evaluation of Metals - G.A. Georgiou ©Encyclopedia of Life Support Systems (EOLSS) difficult to detect by conventional methods. The defects and NDT methods discussed are summarized in tables for each

Correlation Between Non-Destructive Testing…. www.ijesi.org 14 Page compressive strength. The compressive strength and rebound number were also seen to increase with curing age. These trends are similar to the findings reported by [4]. Table 5,6 and 7 shows the results of regression analysis 09-04-2018 · the difference between destructive and non-destructive testing for casting Sdlinc More details visit SDLINC

18-03-2016 · This study compared destructive and nondestructive testing techniques to evaluate the abrasion resistance of concrete. Eight concrete hardeners (six solid and two liquid) were subjected to abrasion, ultrasound, and rebound hammer tests. The results of the trials were compared to identify the concrete hardeners that provide more abrasion strength, and also to determine the relationships … National Composites Network Best Practice Guide Non-Destructive Testing of Composite Materials Best Practice Guides 6/8/07 3:30 pm Page 4

This investigation covers measurement of surface preparations, evaluation of bond properties by pullout tests, detection of fiber alignment, and detection of delaminations formed between concrete substrate and carbon fiber reinforced polymer (CFRP) by non-destructive testing equipments. Several nondestructive testing systems were performed such destructive and non destructive testing, what are mechanical test conducted in destrective test non destructive test in plate, surface hardness methods for non destructive test on concretesurface hardness methods for non destructive test on concrete, destructive and nondestructive testing, guidebook onnon destructive testing of concrete structures, difference between destructive and non destructive testing …

11-04-2017 · Samson et al., (2014) investigated about the correlation between nondestructive and destructive testing of compressive strength of concrete. Concrete cubes of size (100x100x100mm) were cast using M20, M30, and M35 grade concrete and were cured for 7, 14 and 28 days. Preliminary tests were performed on materials. Total of 90 cubes were produced In a method of localising damages or defects in objects or in materials a standing wave is generated within the object (6) or in the material to be tested. This standing wave is substantially limited to a small area in the object or the material, between a vibration surface and another surface (8) in the object or in the material in order to detect damages or defects within said area of the object or the material from …

NON DESTRUCTIVE. METHODS FOR TESTING OF CONCRETE By DEEPAK KUMAR M.E. Structures (1st Year). Definition of NDT It is defined as the course of inspecting, testing, or evaluating materials, components or assemblies without destroying the serviceability of the part or system.. Testing methods that do not affect the future usefulness of a part or system are considered to be non-destructive even … In destructive testing (or destructive physical analysis, DPA) tests are carried out to the specimen's failure, in order to understand a specimen's performance or material behavior under different loads.These tests are generally much easier to carry out, yield more information, and are easier to interpret than nondestructive testing.Destructive testing is most suitable, and economic, for objects which will be …

08-05-2013 · Radiography Testing48www.sajetc.comRadiography Testing (RT), or industrialradiography is a nondestructive testing (NDT)method of inspecting materials for hidden flawsby using the ability of short wavelengthelectromagnetic radiation (high energy photons)to penetrate various materials.Radiographic Testing Method is nothing but totake the shadow picture of an object onto a … This investigation covers measurement of surface preparations, evaluation of bond properties by pullout tests, detection of fiber alignment, and detection of delaminations formed between concrete substrate and carbon fiber reinforced polymer (CFRP) by non-destructive testing equipments. Several nondestructive testing systems were performed such

Difference Between. DT & NDT DT- Destructive NDT- Non Test Destructive Test The process of inspecting, Atestingtechnique in testing, or evaluating which the application is materials, components or made to fail in an assemblies for uncontrolled manner discontinuities, or totestthe robustness of differences in the application and also characteristics without to find the point of destroying the … The Introduction to Engineering (NGN 110 ) course walks freshman engineering students at AUS through the various engineering fields and demonstrations of some applications of each field. This lab report illustrates the two of the prominent methods of

Correlation Between Non-Destructive Testing…. www.ijesi.org 14 Page compressive strength. The compressive strength and rebound number were also seen to increase with curing age. These trends are similar to the findings reported by [4]. Table 5,6 and 7 shows the results of regression analysis Comparison between destructive and nondestructive sampling of sessile epibenthic organisms132 Abstract-One subset of a series of identical fouling panels was observed by a nondestruc- tive sampling technique and results were compared with those from a second subset of panels which was destructively sampled. Ini- tially there was no evidence for differences in development of organisms on the panels …

11-04-2017В В· Samson et al., (2014) investigated about the correlation between nondestructive and destructive testing of compressive strength of concrete. Concrete cubes of size (100x100x100mm) were cast using M20, M30, and M35 grade concrete and were cured for 7, 14 and 28 days. Preliminary tests were performed on materials. Total of 90 cubes were produced The destructive testing results of the rubber-filled concrete were then coupled with nondestructive testing (NDT) evaluation. The scope of this effort was first to use a well-accepted NDT method for evaluating this specific PCC type, and second, to correlate strength and static elastic modulus to parameters evaluated from the dynamic NDT